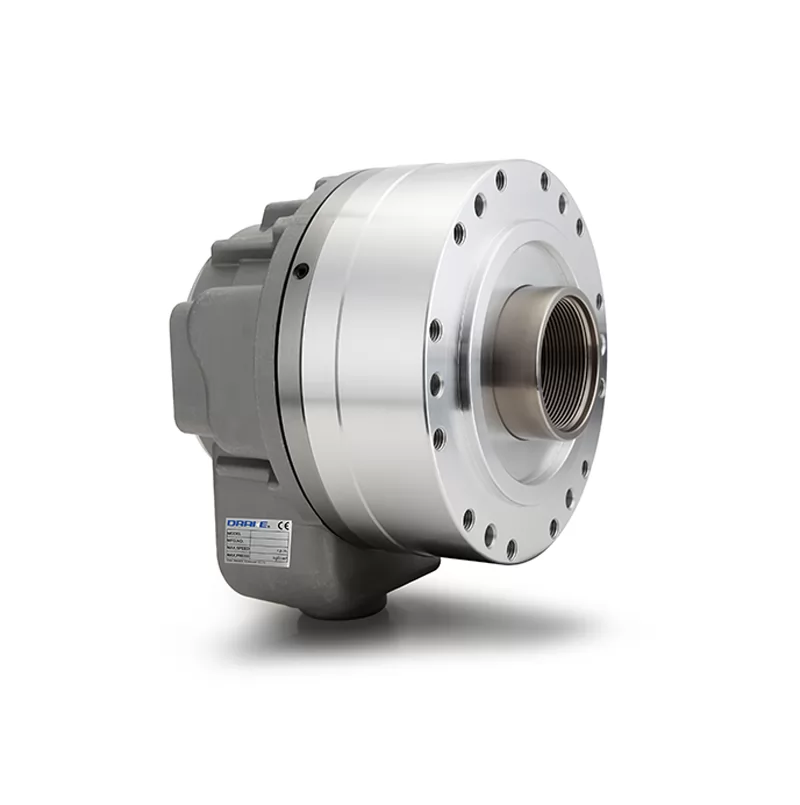

Product Details

The machine tool's center frame includes a clamping device for holding the shaft-like workpiece support to be machined.

It can reciprocate along the machine's guide rails relative to the machine's spindle housing through a mounting hole.

The device is mounted on the support shaft, fitting within the mounting hole and coaxial with the machine's spindle.

One end of the shaft is connected to the clamping device and can rotate about its own axis.

It is positioned independently of the finished outer diameter, preventing damage to the workpiece surface.

It exhibits excellent rigidity when machining high-pitch threads on the right side, minimizing roundness errors in the machined area.

In mechanical manufacturing, it is often necessary to machine the outer diameter, inner hole, end profile,

and threading of slender shaft parts. In traditional external cylindrical turning,

the workpiece is generally clamped using a one-clamp, one-support clamping method.

To increase workpiece rigidity, the center of the workpiece is generally supported by a machine tool center rest.

When machining the end profile, inner hole, and internal thread, a clamping method is generally used,

where one end is clamped and the other end is supported by a center rest.

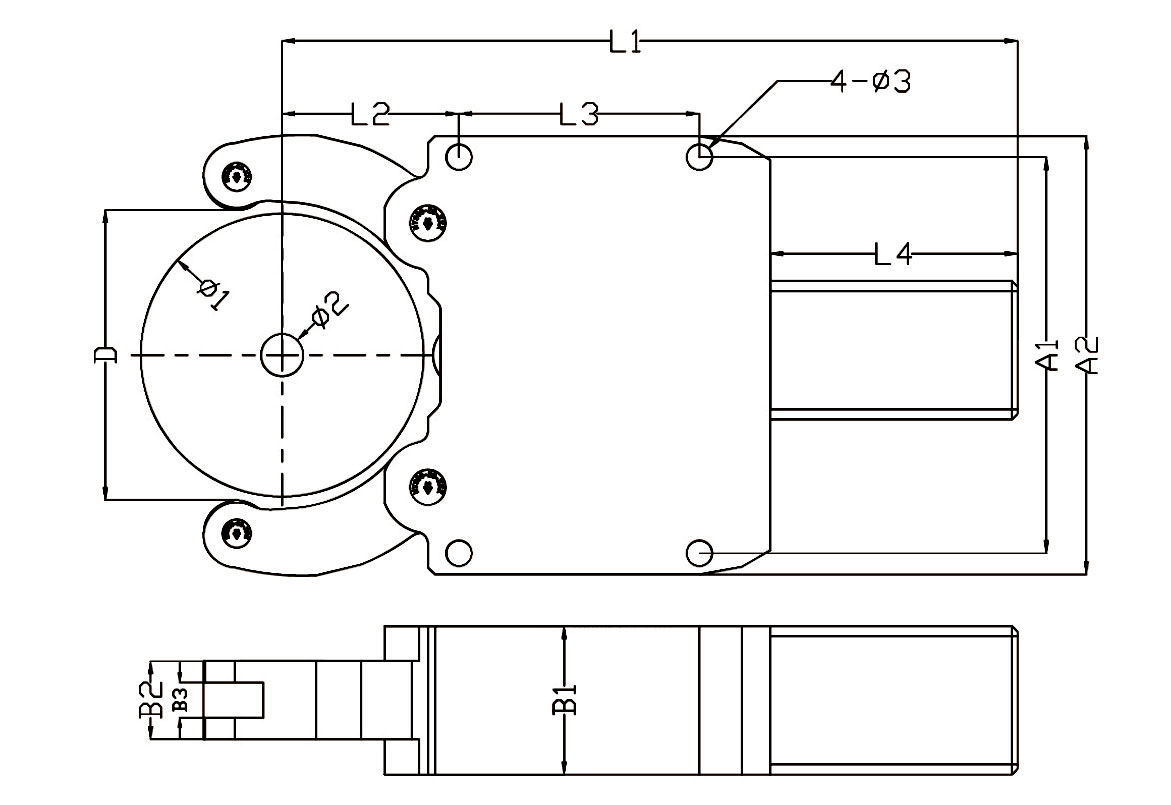

Product Size

Product Parameters

| HY-B(C) series center stand specifications, dimensions and technical performance parameters | |||||||||

| Model | HY115B | HY170B | HY220B | HY260B | HY310B | HY350B | HY420B | HY520C | HY650C |

| Clamping diameter range | φ15-φ115 | φ20-φ170 | φ40-φ220 | φ35-φ260 | φ50-φ310 | φ75-φ350 | φ115-φ420 | φ150-φ520 | φ250-φ650 |

| L1(mm) | 279 | 394 | 479 | 517 | 550 | 600 | 648 | 658 | 798 |

| L2(mm) | 83 | 116 | 136 | 157 | 177 | 229 | 258 | 278 | 403 |

| L3(mm) | 92 | 160 | 202 | 230 | 270 | 240 | 270 | 315 | 300 |

| L4(mm) | 55 | 60 | 60 | 60 | 30 | 30 | 30 | 30 | 35 |

| A1(mm) | 190 | 258 | 341 | 360 | 400 | 461 | 440/475 | 560/680 | 750/625 |

| A2(mm) | 215 | 285 | 372 | 392 | 442 | 499 | 510 | 750 | 812 |

| B1(mm) | 85 | 95 | 110 | 110 | 125 | 125 | 136 | 155 | 175 |

| B2(mm) | 45 | 55 | 60 | 60 | 75 | 75 | 72 | 95 | 95 |

| B3(mm) | 15 | 25 | 25 | 25 | 29 | 29 | 29 | 32 | 32 |

| φ1(mm) | 115 | 170 | 220 | 260 | 310 | 350 | 420 | 520 | 650 |

| φ2(mm) | 15 | 20 | 40 | 35 | 50 | 70 | 115 | 150 | 250 |

| φ3(mm) | 14 | 18 | 18 | 22 | 22 | 22 | 22 | 22 | 26 |

| D(mm) | 118 | 176 | 226 | 268 | 311 | 355 | 420 | 520 | 655 |

| Working Pressure (MPa) | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 |

| Working Range Centering Accuracy | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.06 | 0.07 | 0.08 | 0.09 |

| Repeat | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 |

| Net Weight (kg) | 23 | 48 | 88 | 94 | 138 | 168 | 198 | 318 | 438 |